Inclined conveyor systems play a crucial role in the industrial landscape of Surat, a city known for its thriving textile, manufacturing, and logistics industries. These conveyors are designed to move materials between different heights, making them essential for operations that require efficient vertical transport of goods. This comprehensive guide explores the importance, features, applications, and considerations of inclined conveyor systems in Surat.

Inclined conveyor systems are conveyors that transport goods at an angle from one level to another. They are widely used in industries where products need to be moved between floors, loading docks, or different stages of production. The belt of the inclined conveyor is usually fitted with cleats or ridges to prevent materials from sliding back, ensuring smooth transportation even at steep angles.

In Surat’s bustling industries, where the optimization of space and efficiency is paramount, inclined conveyor systems offer a solution for transporting goods vertically without taking up valuable floor space

Key Features of Inclined Conveyor Systems

Inclined conveyor systems are designed with specific features to address the unique demands of vertical material handling:

- 1. Adjustable Incline: These conveyors can be adjusted to different angles to accommodate the specific needs of the product being handled and the height difference between the loading and unloading points.

- 2. Robust Construction: Built from durable materials like stainless steel or heavy-duty plastic, inclined conveyors are designed to withstand the harsh industrial environment of Surat.

- 3. Smooth Belt Operation: The belt’s design is crucial for maintaining a continuous flow of materials. High-quality belts ensure that goods move smoothly without damage or disruption.

- 4. Customizable Designs: Inclined conveyors can be tailored to the specific requirements of each operation, including customizable belt widths, lengths, and incline angles to fit various production setups.

Benefits of Inclined Conveyor Systems in Surat’s Industries

The advantages of using inclined conveyor systems in Surat are significant, particularly in industries like textiles, manufacturing, and logistics:

- 1. Increased Efficiency: Inclined conveyor systems automate the movement of goods between different heights, speeding up production processes and reducing manual handling. This is particularly important in Surat, where industries often run on tight schedules and require efficient material flow.

- 2. Space Optimization: Given Surat’s industrial density, making the most of available space is crucial. Inclined conveyors help maximize vertical space, freeing up floor area for other operations or equipment.

- 3. Reduced Manual Labor: By automating vertical transport, these conveyors reduce the need for workers to manually lift and carry heavy goods, minimizing the risk of injury and improving overall workplace safety.

- 4. Versatility: Inclined conveyors can handle a variety of materials, from textiles to heavy machinery, making them suitable for a wide range of industries. Their versatility is especially valuable in Surat’s diverse industrial landscape.

- 5. Cost-Effectiveness: Though the initial investment in inclined conveyor systems may be high, the long-term benefits—such as reduced labor costs, faster production times, and fewer injuries—make them a cost-effective solution for many businesses in Surat.

Applications of Inclined Conveyor Systems in Surat

- a. Textile Industry: Surat is well-known for its textile industry, producing fabrics, garments, and accessories that are exported across the globe. Inclined conveyor systems are essential in textile mills and factories, where they are used to transport fabric rolls and finished garments between different levels of the production facility. These conveyors help streamline production and reduce the time and effort needed to move materials manually.

- b. Manufacturing: In Surat’s manufacturing sector, inclined conveyor systems are used to move raw materials, components, and finished products between different production stages. These systems are particularly useful in facilities that handle heavy or bulky materials, such as machinery or metal parts. Inclined conveyors reduce the strain on workers and improve the overall efficiency of manufacturing processes.

- c. Food Processing: Food processing is another industry in Surat that benefits from inclined conveyor systems. These conveyors are used to move bulk ingredients or finished products vertically, ensuring that food materials are transported efficiently and hygienically between different processing stages. Inclined conveyors with food-grade belts are particularly valuable in maintaining product safety and quality.

- d. Logistics and Warehousing: In logistics and warehousing operations, inclined conveyors help move goods from storage areas to loading docks or trucks, improving the speed and efficiency of loading and unloading processes. In Surat’s fast-paced logistics industry, where quick turnaround times are critical, inclined conveyor systems are a valuable tool for enhancing operational efficiency.

Considerations for Installing Inclined Conveyor Systems

When implementing inclined conveyor systems in Surat’s industrial environment, several factors need to be taken into account:

- a. Material Compatibility: It’s essential to choose a conveyor belt material that suits the type of goods being transported. For example, food-grade belts are necessary for food processing operations, while heavy-duty belts are required for transporting industrial machinery or textiles.

- b. Space and Layout: The layout of the facility and available space play a crucial role in the design and installation of inclined conveyors. The incline angle, belt length, and conveyor placement should be optimized to fit the specific spatial constraints and operational flow of the facility.

- c. Durability and Maintenance: Given Surat’s humid climate and the demanding conditions in some industries, the materials used to build inclined conveyors must be durable and corrosion-resistant. Stainless steel or reinforced plastic components are ideal for ensuring longevity. Regular maintenance is also important to keep the conveyor running smoothly and to prevent breakdowns.

- d. Regulatory Compliance: It’s crucial that inclined conveyor systems comply with industry-specific regulations and safety standards. In food processing plants, for example, the conveyors must meet strict hygiene requirements, while in manufacturing facilities, safety features like emergency stop buttons and guards should be in place to prevent accidents.

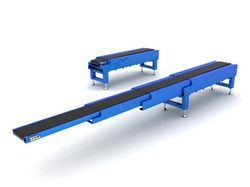

If you want to incline a bulky material to match a production line or to give support to your employees, then Perfection Engineering Corporation is here for you with their best-inclined conveyors systems to offer you the necessary flexibility. The inclined conveyor systems we provide, come with equipped infeed, outfeed, and horizontal sections to provide better product handling control. Our inclined conveyor systems are perfect for doing product transferring as per the needs of the buyers.

We also offer Inclined Conveyor Systems in multiple cities like in Delhi, Gurgaon, Kolkata, and in many more...