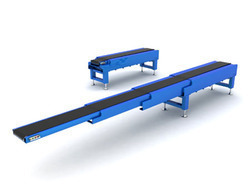

Perfection Engineering Corporation offers a complete range of products such as flat top modular belt conveyor and bends modular belt conveyors.

We manufacture our qualitative range of Modular Belt Conveyors by using the latest technology; these conveyors are fabricated with powder coating to make sure that it becomes corrosion resistance and durable. Our products are further tested on the international quality parameter to ensure that they have no defect left in them.

The modular belt conveyor in indore that we provide cater to the material handling needs of automotive, food, and other industries. Our modular belt conveyors give optimum performance and high level of durability. Having the motto of providing best customer service, we have become a leading company in providing the most cost-efficient, low priced, and technologically innovative modular belt conveyors in the market. We also offer the customized modular belt conveyors so that our products can meet the specific application needs of our valued customers.

Modular belt conveyors are specialized conveyor systems that use interlocking, flexible plastic or metal segments to create a belt. These conveyors are highly adaptable and are widely used in various industries for transporting products efficiently. Indore, with its growing industrial sector, especially in food processing, pharmaceuticals, and manufacturing, has seen a significant rise in the adoption of modular belt conveyors due to their durability, versatility, and low maintenance requirements.

Types of Modular Belt Conveyors

Modular belt conveyors come in a range of types, depending on the design, materials, and applications. Some of the common types used in Indore's industries include:

- Straight Modular Belt Conveyors: These conveyors are the most commonly used, designed for moving products in a straight line. They are ideal for industries like food processing, where sanitation is critical, and the easy-to-clean design of modular belts offers significant advantages.

- Inclined Modular Belt Conveyors: These conveyors are designed to transport products at an incline. They are often used to move products between different levels in a facility or load products into packaging machines.

- Curved Modular Belt Conveyors: These systems are designed to navigate around bends and curves, allowing for flexible conveyor layouts within limited space. They are commonly used in airports, manufacturing plants, and large warehouses.

- Side Flexing Modular Belt Conveyors: This type of conveyor is used for applications that require complex layouts, including moving around corners or obstacles. They are ideal for industries that require a high degree of flexibility in production lines.

- Heavy-Duty Modular Belt Conveyors: Designed for transporting heavier loads, these conveyors are used in industries like construction, automotive, and industrial manufacturing, where robust performance is essential.

Applications of Modular Belt Conveyors in Indore

Modular belt conveyors are versatile and find applications in a wide range of industries in Indore. Their modular design, easy maintenance, and durability make them suitable for handling a variety of products. Some key applications include:

- Food and Beverage Industry: Modular belt conveyors are widely used in food processing plants in Indore for transporting packaged goods, raw ingredients, and processed foods. The belts' sanitary design makes them easy to clean, ensuring hygiene standards are maintained.

- Pharmaceutical Industry: In pharmaceutical manufacturing facilities, modular belt conveyors are used to handle products such as bottles, cartons, and packages. The belts provide a reliable and contamination-free way of moving products through production lines.

- Automotive Industry: Heavy-duty modular belt conveyors are commonly used in Indore's automotive manufacturing sector for transporting car parts and components. These conveyors are capable of handling the weight and size of large automotive parts efficiently.

- Packaging Industry: Modular belt conveyors are essential in packaging facilities, where they are used to move products from one packaging station to another. The flexibility of the belt design allows for the handling of a wide range of package sizes and shapes.

- Logistics and Warehousing: In large warehouses and distribution centers in Indore, modular belt conveyors help streamline the movement of goods between different areas. Their ability to move products through straight, inclined, or curved paths makes them an efficient solution for intralogistics.

Benefits of Modular Belt Conveyors

Modular belt conveyors offer numerous advantages that make them a popular choice for industries in Indore. Some of the key benefits include:

- Durability: Modular belts are designed to withstand harsh conditions and handle a variety of materials. Their interlocking segments are made from high-quality plastics or metals, ensuring long-lasting performance.

- Easy Maintenance: One of the key advantages of modular belt conveyors is the ease of maintenance. Damaged segments can be quickly replaced without having to replace the entire belt, reducing downtime and repair costs.

- Customizable Layouts: Modular belts can be configured to meet the specific needs of the facility. They can move products horizontally, vertically, or around corners, providing flexibility in production and storage environments.

- Sanitation and Cleanliness: The smooth, non-porous surface of modular belts ensures easy cleaning, making them ideal for industries like food and pharmaceuticals, where hygiene is critical.

- Energy Efficient: Modular belt conveyors are designed to be energy-efficient, with low power requirements for operation. This makes them cost-effective for long-term use in industrial applications.

Maintenance and Safety Tips for Modular Belt Conveyors

Proper maintenance is essential for ensuring the smooth operation and longevity of modular belt conveyors. Here are some tips for maintaining and safely operating these systems:

- Regular Inspection: Regularly inspect the conveyor belt for signs of wear and tear, especially in high-stress areas like joints and links. Replace damaged or worn segments promptly to avoid system breakdown.

- Lubrication: Ensure that all moving parts, such as motors and bearings, are well-lubricated to reduce friction and wear. This will help extend the lifespan of the conveyor system.

- Cleaning: Clean the conveyor belts regularly, especially in industries like food processing, where sanitation is critical. Ensure that all contaminants are removed, and the belts are disinfected as needed.

- Belt Tensioning: Check the tension of the belt regularly to ensure optimal performance. A belt that is too tight can cause damage, while a loose belt may lead to slippage and inefficient operation.

- Safety Protocols: Implement safety protocols for workers operating or maintaining the conveyor system. Ensure that all safety guards are in place, and emergency stop buttons are accessible.

We also provide Modular Belt Conveyors in multiple cities like in Pune, Bangalore, Hyderabad, and in many more as per reqirements.