Indore, one of the industrial hubs of Madhya Pradesh, is home to a wide range of manufacturing and processing units. To keep up with the growing demand for automation and efficient material handling, industries in Indore are increasingly adopting advanced conveyor systems. Among these, infeed conveyor systems play a crucial role in streamlining production lines and ensuring smooth material transfer processes. This article explores the various aspects of infeed conveyor systems, their advantages, applications, and how they are helping industries in Indore improve productivity and operational efficiency.

What is an Infeed Conveyor System?

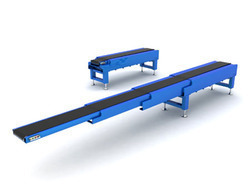

An infeed conveyor system is a type of conveyor specifically designed to move materials or products into a machine, processing line, or other downstream systems. The primary function of infeed conveyors is to feed materials accurately, quickly, and efficiently into equipment such as packaging machines, sorters, or processing machines. These conveyors are crucial for optimizing the input process, ensuring consistent material flow, reducing manual handling, and minimizing the chances of bottlenecks in production lines.

Types of Infeed Conveyor Systems

Infeed conveyor systems come in various types depending on the specific requirements of the application. Some of the most common types of infeed conveyors used in Indore's industries include:

- Belt Infeed Conveyors: These are widely used for transporting lightweight to medium-weight products. The belt system ensures smooth and continuous movement of materials into the machine.

- Roller Infeed Conveyors: Ideal for heavier loads, roller infeed conveyors use rollers to transfer materials along the conveyor path. They are often used for bulky items and products with irregular shapes.

- Chain Infeed Conveyors: These are used for transporting heavy-duty materials, including industrial parts, metal components, and other large items. The chain provides robust support for high loads.

- Vibratory Infeed Conveyors: These conveyors use vibration to move materials along the system, particularly useful for granular or powdery materials that may not flow easily on traditional belts or rollers.

- Inclined Infeed Conveyors: These are designed to move materials to a higher elevation, often feeding into machines positioned above ground level. They are equipped with cleats or textured surfaces to prevent product rollback.

Advantages of Infeed Conveyor Systems

Infeed conveyor systems offer several benefits that make them an essential component in modern industrial setups. Here are some key advantages:

- Increased Efficiency: Infeed conveyors automate the material handling process, reducing the need for manual labor and increasing the speed of product transfer into machines.

- Precise Material Handling: These systems ensure that products are fed into machines in a controlled and consistent manner, reducing the risk of jams, product damage, and other issues that could slow down the production line.

- Reduction in Downtime: Infeed conveyors contribute to smoother workflows by eliminating manual input processes that can cause delays or inconsistencies, reducing downtime and ensuring continuous operations.

- Customizable: Infeed conveyors can be customized to suit the specific needs of an industry. From belt type and speed to the angle of incline and material strength, businesses in Indore can design the perfect system for their requirements.

- Improved Safety: Automation reduces the need for workers to handle materials directly, improving safety by reducing the risk of injuries associated with heavy lifting or manual material handling.

- Integration with Automation: Infeed conveyor systems are often integrated into larger automated systems, including packaging lines, sorting systems, and robotic machinery. This integration helps improve overall operational efficiency.

Applications of Infeed Conveyor Systems in Indore

Infeed conveyor systems have a wide range of applications in Indore's industries, thanks to their versatility and ability to handle different types of materials. Some of the key industries that utilize infeed conveyor systems include:

- Food Processing: In Indore's thriving food processing industry, infeed conveyors are used to feed ingredients into mixers, slicers, and packaging machines. These conveyors ensure the timely delivery of ingredients, streamlining the food production process.

- Packaging: In packaging facilities, infeed conveyor systems are crucial for feeding products like boxes, bottles, and pouches into packaging machines. The systems ensure that products are accurately positioned and fed into the machines without interruptions.

- Automotive Industry: Indore's automotive parts manufacturers use infeed conveyors to transport heavy components like metal parts, engines, and assemblies into machining centers or robotic arms for further processing.

- Pharmaceuticals: In pharmaceutical production, infeed conveyors help move bottles, capsules, and powders into filling and packaging machines, ensuring that the production line runs smoothly and efficiently.

- Agriculture: In agriculture, infeed conveyors are used to transport harvested crops and grains into processing units, providing a streamlined material handling solution that minimizes damage to products.

Factors to Consider When Choosing an Infeed Conveyor System

Selecting the right infeed conveyor system is critical to ensuring the efficiency and productivity of your production line. Here are some key factors to consider when choosing an infeed conveyor system in Indore:

- Type of Material: The type of product being handled will dictate the type of infeed conveyor you need. For instance, lightweight products may require a belt conveyor, while heavier items might need a roller or chain conveyor.

- Load Capacity: It's essential to choose a conveyor that can handle the weight and volume of your materials to avoid system overload and ensure long-term reliability.

- Speed Requirements: Different production lines may require varying speeds of material handling. Look for conveyors that offer adjustable speeds to meet your specific operational needs.

- Space Constraints: Consider the available space in your facility and select a conveyor system that fits within the layout without disrupting other operations.

- Integration Capabilities: If your infeed conveyor needs to work in tandem with other automated systems, such as packaging lines or robotic arms, ensure that it can be seamlessly integrated with these technologies.

We, at Perfection Engineering Corporation, design the range of infeed conveyor systems by consulting trustworthy vendors for getting the good quality raw material and innovative machines so that a good verse production unit can be created.

Also we provided Infeed Conveyor System in multiple cities like in Surat, Pune, Bangalore, and in many more...