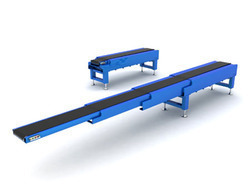

If you want to incline a bulky material to match a production line or to give support to your employees, then Perfection Engineering Corporation is here for you with their best-inclined conveyors systems to offer you the necessary flexibility. The inclined conveyor systems we provide, come with equipped infeed, outfeed, and horizontal sections to provide better product handling control. Our inclined conveyor systems are perfect for doing product transferring as per the needs of the buyers.

Inclined conveyor systems are vital for moving materials between different elevation levels in various industries, such as logistics, manufacturing, and agriculture. These conveyors are particularly popular in Indore, a city with a thriving industrial sector. The inclined design helps in the efficient transfer of materials, making them indispensable in optimizing production processes and improving workplace efficiency.

Types of Inclined Conveyor Systems

Inclined conveyor systems are designed in various configurations to meet different industrial requirements. Common types include:

- Inclined Belt Conveyors: One of the most widely used types, inclined belt conveyors are designed with a rubber or synthetic belt that can handle everything from bulk materials to packages.

- Inclined Roller Conveyors: These conveyors use gravity or motorized rollers to move items up or down an incline, suitable for boxes, containers, and larger items.

- Inclined Screw Conveyors: A helical screw inside a tube moves materials such as grains, powders, or granules along an incline, typically used in industries like agriculture or food processing.

- Modular Inclined Conveyors: Constructed from modular components, these conveyors offer flexibility and can be easily customized for various applications.

- Portable Inclined Conveyors: These are designed for mobility, making them ideal for temporary setups in industries like construction or warehousing.

Applications of Inclined Conveyor Systems

Inclined conveyor systems are widely used across industries in Indore. Some of their key applications include:

- Manufacturing: Used to transport raw materials or finished products between different production levels or assembly lines, ensuring continuous workflow.

- Logistics and Warehousing: Inclined conveyors assist in moving packages or goods from loading docks to storage areas or between different floors in large warehouses.

- Food Processing: In the food industry, inclined conveyors are used for transporting food items like fruits, vegetables, grains, and packaged products, adhering to stringent hygiene standards.

- Construction: Portable inclined conveyors are used to transfer construction materials such as sand, gravel, or concrete to elevated areas or over uneven terrain.

- Agriculture: Inclined conveyors help transport grains, seeds, and fertilizers in agricultural facilities or between storage areas.

Benefits of Inclined Conveyor Systems

Inclined conveyor systems offer several advantages, making them a popular choice in Indore's industrial landscape. These include:

- Space Optimization: By utilizing vertical space, inclined conveyors help maximize floor space in manufacturing plants, warehouses, and storage areas.

- Cost-Efficient: Automating material movement reduces labor costs and increases operational efficiency, minimizing the time needed for manual handling.

- Safety and Ergonomics: Inclined conveyors reduce the need for manual lifting of heavy materials, improving safety for workers and reducing the risk of workplace injuries.

- Versatility: These conveyors can handle a wide variety of materials, from bulk items to delicate goods, making them suitable for multiple industries.

- Customizability: Inclined conveyor systems can be customized to meet specific length, height, and load-bearing requirements for different applications.

Key Features of Inclined Conveyor Systems

Inclined conveyor systems in Indore are designed with specific features to enhance functionality and durability:

- Durable Construction: Made from materials like stainless steel or heavy-duty plastic, these conveyors are built to handle rigorous operations and withstand wear and tear.

- Adjustable Incline: Many systems feature adjustable inclines, allowing users to modify the angle based on specific operational needs or the type of material being transported.

- High Load Capacity: Designed to carry heavy loads, inclined conveyor systems can move materials efficiently across different heights without compromising on speed or reliability.

- Low Maintenance: Inclined conveyors are engineered with minimal moving parts, reducing the need for frequent maintenance and ensuring consistent performance over time.

- Safety Features: Equipped with safety guards, emergency stop buttons, and anti-slip belts, inclined conveyor systems prioritize operator safety.

Maintenance of Inclined Conveyor Systems

Regular maintenance is essential to ensure that inclined conveyor systems operate efficiently and have a long service life. Key maintenance practices include:

- Regular Inspection: Conduct routine checks to identify any wear or misalignment in belts, rollers, or screws. Timely detection helps in avoiding costly repairs or replacements.

- Belt Tensioning: Check and adjust belt tension regularly to prevent slippage and ensure smooth material movement. Over-tightening should be avoided as it may damage the belt.

- Lubrication: Lubricate motor parts, chains, and rollers as per manufacturer recommendations to reduce friction and wear on moving parts.

- Cleaning: For industries like food processing, keeping the conveyor system clean is vital to maintain hygiene and prevent contamination.

- Safety Checks: Test all safety mechanisms, such as emergency stop buttons and guarding, to ensure they are functional and compliant with industry regulations.

- Professional Servicing: Engage professional services for detailed inspections and repairs, particularly for motorized or automated inclined conveyor systems.

We also provide Inclined Conveyor Systems in multiple cities like in Ghaziabad, Kanpur, Faridabad, and in many more...