As there are numerous alternatives available in the market, choosing the suitable cleat conveyors is very important. We, at Perfection Engineering Corporation;, are the leading company in providing the best cleat conveyor systems in regions like Ghaziabad, Gurgaon, Faridabad, and in many more. We use stable and efficient belts at the time of manufacturing the conveyor systems as they work for a longer period. As, in today’s world, the need for transporting heavy and bulky materials is increasing, the use of cleat conveyors is also rising side by side.

Indore, being one of the most industrially progressive cities in Madhya Pradesh, has seen significant growth in the manufacturing and warehousing sectors. Among the essential equipment used in these industries, cleat conveyors play a pivotal role. Cleat conveyors are specially designed for transporting bulk materials at steep angles or even vertically, thanks to the cleats or barriers attached to the belt, which help prevent material rollback during transit. In Indore, various industries benefit from this conveyor system, including the food processing, agriculture, pharmaceuticals, and packaging sectors. This article provides an in-depth understanding of cleat conveyors, their benefits, and their applications in Indore's industrial landscape.

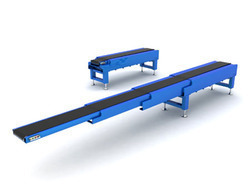

What is a Cleat Conveyor?

A cleat conveyor, also known as a cleated belt conveyor, is a type of belt conveyor that incorporates raised cleats or ridges attached at intervals along the belt. These cleats help carry materials up inclined surfaces, ensuring that products or bulk materials do not slide back or fall off. Cleats come in various shapes and sizes, depending on the material being transported and the angle of incline. Common cleat designs include T-shaped, V-shaped, and L-shaped cleats. These conveyors are often used when handling granular, powdery, or irregularly shaped materials that require secure transport over a distance.

Advantages of Cleat Conveyors

Cleat conveyors offer several advantages for industrial applications in Indore:

- Efficient Material Handling: Cleat conveyors enable the movement of materials at steep angles, reducing the need for additional space in horizontal layout configurations. This efficiency is especially valuable in compact industrial setups.

- Prevents Material Rollback: The cleats on the belt provide grip and hold to the material, preventing it from rolling back, which is crucial when moving bulk items at an incline.

- Versatility: Cleat conveyors are adaptable to different industries, making them suitable for transporting a wide range of products, including grains, seeds, powders, small parts, and more.

- Customizable Designs: Depending on the specific needs of a business, cleat conveyors can be customized with different cleat shapes, sizes, and belt materials to handle different types of goods effectively.

- Durability: Cleat conveyors are built to withstand harsh industrial environments. Many belts are made from robust materials like PVC, rubber, or thermoplastics, which ensure long-lasting performance.

- Increased Productivity: By allowing for faster, more reliable transportation of goods, cleat conveyors help increase the overall productivity of the factory floor.

Applications of Cleat Conveyors in Indore

Cleat conveyors find applications across numerous industries in Indore. The city’s industrial sector is diverse, and businesses that handle bulk materials can greatly benefit from the use of cleat conveyors.

- Food Processing Industry: Indore's food processing plants often use cleat conveyors to transport ingredients like grains, pulses, and powders. Cleat conveyors ensure that the materials are securely moved without spillage, even at steep angles. These systems are commonly employed for packaging, sorting, and ingredient mixing.

- Agriculture: Cleat conveyors are widely used in agriculture to transport grains, seeds, and other agricultural products. The cleats provide secure transport, preventing material loss and enhancing efficiency in bulk handling processes.

- Pharmaceuticals: In Indore’s pharmaceutical industry, cleat conveyors are used for the transport of delicate materials such as powders and capsules, providing a reliable means of transfer without compromising product integrity.

- Packaging and Warehousing: Warehousing operations in Indore benefit from cleat conveyors to move packaged products, cartons, and other items efficiently across varying elevations. This type of conveyor is ideal for loading and unloading products in a warehouse setting.

- Construction and Mining: Cleat conveyors are utilized in construction and mining industries in Indore for the transportation of heavy bulk materials, such as sand, gravel, and minerals, which need to be carried at steep inclines.

Factors to Consider When Choosing a Cleat Conveyor in Indore

When selecting a cleat conveyor in Indore, businesses should consider several factors to ensure they choose the right system for their needs:

- Material Type: The type of material being transported (e.g., granular, powdered, or solid) will determine the design and size of the cleats.

- Angle of Incline: The steepness of the incline will influence the cleat design. For steeper inclines, larger or more aggressive cleats may be required.

- Belt Material: The material of the conveyor belt must be suitable for the environment and the type of material being transported. Options include rubber, PVC, and thermoplastic belts.

- Load Capacity: The conveyor’s load capacity should match the weight and volume of the materials being transported to ensure efficient and safe operation.

- Customization Needs: Businesses with unique requirements should opt for suppliers that offer customized conveyor solutions, tailored to their specific applications.