Perfection Engineering Corporation provides different types of chain conveyors to our respected customers as per their requirements. Chain conveyors are fixed between two strands of chain which drags the material from one end to another Chain Conveyor in Indore. We ensure efficient material handling solutions for various industries.

Chain conveyors are a popular material handling solution widely used in a variety of industries. These conveyors consist of a series of interconnected chains that are driven by motors, making them ideal for transporting heavy loads across industrial settings. In Indore, a growing industrial hub, chain conveyors are commonly used in sectors such as manufacturing, automotive, food processing, and more due to their ability to handle robust materials and ensure efficient workflow.

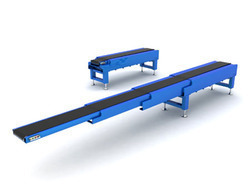

The chain conveyors are available in different lengths and widths and are used to handle slightly loose, sluggish, or lumpy hot material.

Types of Chain Conveyors

Chain conveyors come in different designs, each suited for specific applications. Below are some of the most common types used in industries across Indore:

- Drag Chain Conveyors: These are used for handling bulk materials. The chains drag materials along a trough, making them suitable for transporting items like grain, coal, and other bulk materials across long distances.

- Slat Chain Conveyors: In slat conveyors, slats are attached to the chain, providing a flat surface to transport objects. They are used for handling products like heavy machinery, automotive parts, and goods that require stable support during transit.

- Plastic Chain Conveyors: Designed for lighter materials, plastic chain conveyors are commonly used in food and beverage industries for transporting packaged goods, bottles, and containers. Their lightweight design and corrosion resistance make them ideal for clean environments.

- Roller Chain Conveyors: These conveyors utilize chains and rollers to move products and are often employed in production lines for assembly, packaging, and distribution of goods.

- Multi-Strand Chain Conveyors: Multi-strand conveyors consist of multiple parallel chains that can handle wider and heavier loads, making them perfect for industries dealing with large and bulky materials, such as automotive manufacturing and construction.

Applications of Chain Conveyors in Indore

Chain conveyors are versatile systems that serve various industries in Indore. Below are some of the prominent applications:

- Automotive Manufacturing: Indore's automotive industry extensively uses chain conveyors to transport car parts, engines, and other components across the production line. The durability of chain conveyors allows them to carry heavy loads, ensuring a smooth manufacturing process.

- Food Processing Industry: In Indore’s food processing sector, chain conveyors play a crucial role in transporting raw materials and packaged goods through different stages of production. Their ability to handle a wide range of product sizes makes them essential in both small and large-scale operations.

- Textile Industry: Chain conveyors are used to move rolls of fabric, yarn, and other textile products in Indore’s growing textile industry. The conveyors help streamline production and reduce manual labor, resulting in greater efficiency.

- Heavy Machinery Manufacturing: For industries dealing with heavy machinery, chain conveyors are indispensable in transporting large, heavy parts from one production stage to another. The strength of the chains ensures safe and efficient movement of materials.

- Construction Materials: Chain conveyors are used to move construction materials such as cement, sand, and gravel in Indore's booming construction industry. Their robust design allows them to handle these heavy materials without wear and tear.

Benefits of Using Chain Conveyors

Chain conveyors offer several advantages that make them a preferred choice for industries in Indore. Some of the notable benefits include:

- High Load Capacity: One of the primary advantages of chain conveyors is their ability to carry heavy loads. This makes them ideal for industries that require the transportation of bulky and large materials.

- Durability: Chain conveyors are made from high-quality materials that are built to withstand the wear and tear of industrial environments. This durability ensures a long operational life, making them cost-effective over time.

- Versatility: These conveyors can be customized to handle different types of materials and accommodate various operational needs. From automotive parts to food products, chain conveyors are highly adaptable.

- Efficient Handling of Products: Chain conveyors provide consistent and efficient movement of goods, helping reduce production delays. They are particularly beneficial in environments that require fast and smooth transitions between production stages.

- Low Maintenance: Chain conveyors are relatively low-maintenance compared to other conveyor types. Regular inspections and occasional lubrication of the chains can keep them operating efficiently for years.

Maintenance Tips for Chain Conveyors

Regular maintenance is critical for the smooth operation of chain conveyors and to prevent costly breakdowns. Here are some key tips for maintaining these systems:

- Regular Lubrication: The chains of the conveyor should be regularly lubricated to reduce friction and prevent wear and tear. Proper lubrication ensures the conveyor runs smoothly and minimizes operational noise.

- Inspect for Wear and Damage: Chains, rollers, and other components should be inspected regularly for signs of wear or damage. Early detection of worn-out parts allows for timely replacements and avoids system breakdowns.

- Maintain Proper Tension: The chain tension should be checked periodically to ensure it’s neither too loose nor too tight. Incorrect tension can lead to inefficient operation and potential damage to the conveyor system.

- Cleaning: Regularly clean the conveyor components to remove dust, dirt, and debris that may accumulate during operation. Keeping the system clean reduces friction and prevents damage to the chain links.

- Check Alignment: Ensure that the chain and other conveyor components remain aligned to prevent undue stress on the conveyor system. Misalignment can cause the chains to wear out faster and lead to operational inefficiencies.

We also provide Chain Conveyors in multiple cities like in Pune, Faridabad, Ghaziabad, and in many more...