Perfection Engineering Corporation is present here to fulfill your requirements, without forcing you to compromise. We have the most experienced professionals for manufacturing and supplying the best Industrial Conveyors according to the needs of our valued customers. The use of Industrial Conveyors that we manufacture vary with the kind of product that you will move with the help of conveyor.

An industrial conveyor system is a mechanical handling equipment that is useful in applications that involve transportation of bulky or heavy things. We, at Perfection Engineering Corporation, have our core focus on providing high quality and excellent customer services. We provide different types of conveyors depending on the various needs and desires of the industry. The best industrial conveyor in indore provided by us helps you to quickly and efficiently move a wide variety of materials which in turn makes these conveyors very famous in the packaging and material handling industries.

Industrial conveyors are crucial to automating and streamlining material handling processes in industries like manufacturing, logistics, food processing, and more. In Indore, which has a rapidly growing industrial sector, these systems play a significant role in enhancing productivity and reducing operational costs. Industrial conveyors are used for transporting materials or products between different points in a factory or warehouse, improving workflow and minimizing manual handling.

Types of Industrial Conveyors

There are several types of industrial conveyors commonly used in Indore, depending on the material, application, and industry requirements. These include:

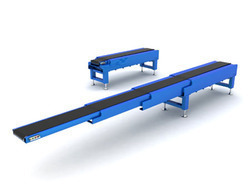

- Belt Conveyors: One of the most popular types, these conveyors use a continuous belt made from materials like rubber, PVC, or fabric. They are suitable for transporting products of varying sizes and weights over long distances.

- Roller Conveyors: Using a series of rollers, this type of conveyor is ideal for transporting heavy or bulky items like crates, boxes, and pallets. Roller conveyors can be gravity-driven or motorized.

- Screw Conveyors: These Screw conveyors use a rotating helical screw to move bulk materials like grains, powders, or granules. They are often used in agriculture, food processing, and chemical industries.

- Chain Conveyors: Suitable for moving heavy items over long distances, chain conveyors use chains to pull or carry products along a track. They are often found in automotive and heavy manufacturing industries.

- Modular Belt Conveyors: Constructed from individual interlocking plastic segments, these modular belt conveyors offer flexibility and are easy to maintain. They are used in industries like food processing, packaging, and pharmaceuticals.

- Inclined Conveyors: Designed to move materials between different elevation levels, inclined conveyors are commonly used in multi-level production facilities or to load trucks or storage systems.

Applications of Industrial Conveyors in Indore

Industrial conveyors are used across a wide range of industries in Indore. Some common applications include:

- Manufacturing: Conveyors are used to move raw materials, components, or finished products through different stages of production, ensuring a streamlined and continuous workflow.

- Logistics and Warehousing: In large warehouses and distribution centers, conveyors are vital for moving packages, pallets, and boxes from one area to another, such as from loading docks to storage or shipping areas.

- Food Processing: Conveyors are used to transport food items like fruits, vegetables, grains, and processed products in a hygienic and controlled manner, ensuring quality and efficiency.

- Automotive Industry: Chain conveyors and roller conveyors are frequently used to move heavy automotive parts, engines, and vehicles through assembly lines and between production facilities.

- Agriculture: In the agricultural sector, conveyors are used to move grains, seeds, fertilizers, and other bulk materials from storage silos to processing units or transport vehicles.

Benefits of Industrial Conveyors

The use of industrial conveyors provides several advantages, especially in the industrial environment of Indore:

- Improved Efficiency: By automating material handling, conveyors significantly reduce the time and labor required to move products or materials between different points, increasing overall productivity.

- Cost Savings: Although conveyors require an initial investment, they quickly pay for themselves by reducing manual labor, minimizing product damage, and speeding up production times.

- Enhanced Safety: Conveyors reduce the need for workers to handle heavy or hazardous materials manually, lowering the risk of workplace injuries and accidents.

- Versatility: Industrial conveyors can handle a wide range of materials, from heavy automotive parts to delicate food products, making them suitable for use across multiple industries.

- Customization: Many conveyor systems can be customized in terms of size, speed, and design to meet the specific needs of an industry or application.

Maintenance and Safety of Industrial Conveyors

Proper maintenance is essential to keep industrial conveyors running smoothly and safely. Some key maintenance practices include:

- Regular Inspections: Periodic inspections of belts, rollers, chains, and motors can help detect signs of wear and tear early, preventing costly breakdowns and ensuring smooth operation.

- Lubrication: Keeping moving parts like chains and rollers well-lubricated helps to minimize friction and wear, extending the lifespan of the conveyor.

- Belt Tensioning: Ensuring the belt is correctly tensioned is vital to prevent slippage or premature wear. Adjustments should be made as per manufacturer guidelines.

- Cleaning: Regular cleaning is especially important in industries like food processing, where hygiene standards must be maintained. Dust and debris should be cleared to prevent blockages or contamination.

- Safety Measures: Installing safety features such as emergency stop buttons, guards, and warning alarms ensures worker safety. Regular checks of these features are crucial to prevent accidents.

- Professional Servicing: Professional servicing from the conveyor manufacturer or a certified technician is recommended for complex repairs or system upgrades.

We also provide Industrial conveyor in multiple cities like in Gurgaon, Bangalore, Jaipur, and in many more...