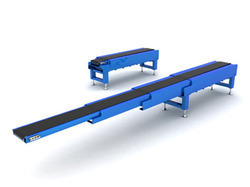

We, at Perfection Engineering Corporation, provide our customers with a wide range of Truck Loading Conveyors which are manufactured by using high-quality raw materials. Our truck loading conveyors are popularly known for their long-lasting performance and durability. We sell our products at the most affordable prices rates so that our respected customers can buy them easily.

These conveyors work in an efficient and compact form for loading bulky bags into the trucks directly. A person is required only to give instructions to the conveyors so that it can successfully stack the bags from the conveyor belt to the truck in layers. Our conveyors are useful for doing simple tasks such as loading and unloading trucks rapidly and efficiently.

With the help of truck loading conveyors, you will be able to defeat the challenge of reaching inside the front of the truck that is faced by every industry when there is lack of manpower and improved technology.

What are Truck Loading Conveyors?

Truck loading conveyors are material handling systems specifically designed to load and unload goods from trucks, trailers, and containers efficiently. These conveyors are typically adjustable in height and length to accommodate different truck sizes and heights. They come in various configurations, including telescopic conveyors, inclined conveyors, and portable conveyors, depending on the specific needs of the facility.

The primary goal of truck loading conveyors is to make the process faster, easier, and safer, minimizing manual labor and reducing the time taken to load or unload vehicles. With their ability to handle bulk materials or packaged goods, they are widely used across industries like manufacturing, warehousing, logistics, and retail.

Benefits of Truck Loading Conveyors

Truck loading conveyors offer several advantages, making them indispensable for industrial operations:

- Increased Efficiency: These conveyors significantly reduce the time it takes to load and unload trucks, improving operational efficiency and allowing for faster turnaround times.

- Reduced Manual Labor: By automating the loading and unloading process, truck loading conveyors reduce the need for manual labor, lowering the risk of injuries and fatigue among workers.

- Cost Savings: With fewer personnel needed for loading and unloading tasks, companies can save on labor costs, while also reducing the risk of damage to goods, leading to further savings.

- Versatility: Truck loading conveyors can handle a wide variety of materials, from boxes and crates to bulk materials, making them ideal for diverse industries such as agriculture, retail, automotive, and more.

- Space Utilization: These conveyors are designed to fit within limited spaces, making the best use of available floor area in loading docks or warehouses.

- Improved Safety: By minimizing the need for manual handling, truck loading conveyors help reduce accidents, injuries, and strain on workers, creating a safer working environment.

- Portability and Flexibility: Many truck loading conveyors are portable or mobile, allowing them to be easily moved and adjusted to meet the specific needs of a facility.

Types of Truck Loading Conveyors

Truck loading conveyors come in various types, each designed for specific loading and unloading tasks. Some of the most common types include:

- Telescopic Conveyors: These conveyors can extend or retract to reach the back of a truck or container, allowing for efficient loading and unloading without manual intervention. Telescopic conveyors are widely used in high-volume facilities where speed and precision are critical.

- Inclined Conveyors: These conveyors are set at an incline, allowing goods to be transported upward or downward between different heights, making them ideal for loading trucks from loading docks at different levels.

- Flexible Conveyors: Flexible or expandable conveyors can be extended, bent, or curved to fit into tight spaces or around obstacles, providing a versatile solution for loading and unloading goods in irregular spaces.

- Portable Truck Loading Conveyors: These are mobile conveyor systems that can be easily transported between locations, making them ideal for facilities with limited space or where conveyor systems need to be relocated frequently.

- Gravity Roller Conveyors: These conveyors rely on gravity to move goods from one point to another, offering a low-cost, energy-efficient solution for loading and unloading trucks when power is unavailable.

Applications of Truck Loading Conveyors in Hyderabad

In Hyderabad, truck loading conveyors are used across a variety of industries to streamline operations. Some of the key industries where these conveyors are widely employed include:

- Logistics and Warehousing: Truck loading conveyors are crucial in logistics hubs and warehouses for loading and unloading goods from trucks, trailers, and containers. They ensure faster turnaround times and improve the overall supply chain process.

- Manufacturing: In the manufacturing sector, truck loading conveyors help move raw materials and finished products efficiently, reducing the time spent loading and unloading trucks at production facilities.

- Retail and E-commerce: Retail and e-commerce companies rely on truck loading conveyors to handle the high volume of packages and goods that need to be loaded and unloaded daily. These conveyors ensure fast, accurate, and safe handling of products.

- Food and Beverage Industry: In the food and beverage industry, truck loading conveyors help transport bulk goods like grains, liquids, and packaged foods, ensuring hygienic and efficient movement from one location to another.

- Construction Materials: For the construction industry, truck loading conveyors are used to load and unload building materials like cement, sand, and bricks, ensuring timely delivery of materials to construction sites.

Key Considerations When Choosing a Truck Loading Conveyor

When selecting a truck loading conveyor system for your facility, it’s essential to consider several factors to ensure optimal performance and cost-effectiveness:

- Capacity: Choose a conveyor system that can handle the volume of goods being loaded or unloaded. Consider the size, weight, and flow rate of the materials you are transporting.

- Flexibility: Some operations may require a conveyor system that can be easily adjusted or moved to different locations. Portable or flexible conveyors are ideal in such cases.

- Space Constraints: Ensure the conveyor fits within the available space while still allowing for efficient operation. Telescopic or expandable conveyors are great for facilities with limited space.

- Durability: Consider the environment in which the conveyor will be used and choose one that can withstand harsh conditions, such as dust, moisture, or heavy loads.

- Safety Features: Look for conveyors equipped with safety features like emergency stop buttons, sensors, and protective guards to prevent accidents and ensure worker safety.

We Perfection Engineering Corporation also provide Truck Loading Conveyorin multiple cities like in Bangalore, Surat, Pune, and in many more...