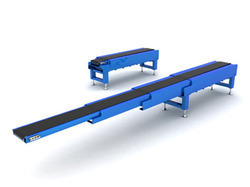

Perfection Engineering Corporation offers a complete range of products such as flat top modular belt conveyor and bends modular belt conveyors.

We manufacture our qualitative range of Modular Belt Conveyors by using the latest technology; these conveyors are fabricated with powder coating to make sure that it becomes corrosion resistance and durable. Our products are further tested on the international quality parameter to ensure that they have no defect left in them.

Modular belt conveyors are specialized conveyor systems composed of interlocking plastic segments,

or "modules," which form a continuous belt. These conveyors are ideal for handling various materials

and products in industries such as food processing, automotive, pharmaceuticals, and packaging.

Hyderabad, a major industrial hub in India, has seen a growing demand for Modular belt conveyors

across its manufacturing and processing industries due to their flexibility, durability, and

low maintenance requirements.

Types of Modular Belt Conveyors

Modular belt conveyors come in several configurations, each designed for specific industrial

applications. Some of the common types include:

-

Flat Top Modular Belt Conveyors: These conveyors feature flat surface belts

and are ideal for transporting products that require smooth, stable support. They are commonly

used in the food and beverage industry.

-

Flush Grid Modular Belt Conveyors: With an open grid design, these conveyors

allow airflow and drainage, making them ideal for wet or cleaning processes, such as in

seafood or vegetable processing industries.

-

Curved Modular Belt Conveyors: These conveyors are designed to transport

products along curved paths, eliminating the need for multiple transfer points and ensuring

seamless product flow.

-

Inclined Modular Belt Conveyors: Designed to move materials vertically or at

an angle, these conveyors are used in industries that require products to be elevated or

lowered between different levels.

Applications of Modular Belt Conveyors

The versatility of modular belt conveyors allows them to be used across a wide range of industries.

In Hyderabad, modular belt conveyors play a crucial role in sectors such as:

-

Food Processing: Modular belt conveyors are used for transporting, washing,

and cooling food products like baked goods, vegetables, and meat. The hygienic design and easy

cleaning features make them ideal for the food industry.

-

Pharmaceutical Industry: These conveyors are employed for moving packaging

materials, medicines, and other products in a controlled and contamination-free environment.

-

Automotive Industry: Modular belts are used to move heavy components such

as engines and vehicle parts on assembly lines. Their durable nature ensures the smooth

transportation of these components.

-

Packaging Industry: Modular belt conveyors are widely used in packaging

plants to transport cartons, bottles, and other packaged items through various stages of

production.

-

Beverage Industry: In bottling plants, modular belt conveyors are used to

move bottles and cans through washing, filling, and capping processes.

Advantages of Modular Belt Conveyors

Modular belt conveyors offer a number of advantages that make them popular in a wide range of

industrial applications:

-

Customizable: The modular design allows for easy customization. Conveyor

lengths, widths, and configurations can be adjusted to meet specific requirements.

-

Durable: Modular belts are built to last. They can handle heavy loads,

resist wear, and are suitable for use in harsh environments.

-

Easy Maintenance: The modular structure makes it easy to replace damaged

sections without the need to replace the entire belt. This reduces downtime and maintenance

costs.

-

Hygienic Design: Many modular belts are designed with open grids that allow

for easy cleaning and drainage. This makes them ideal for industries where hygiene is a

priority, such as food processing and pharmaceuticals.

-

Energy Efficient: These conveyors often require less power compared to other

conveyor systems, leading to lower operational costs.

Maintenance Tips for Modular Belt Conveyors<

Proper maintenance of modular belt conveyors ensures long-term efficiency and reduces the risk of

breakdowns. Some maintenance tips include:

- a. Regularly inspect the modular belt for wear and tear, and replace any damaged sections promptly.

- b. Keep the conveyor clean, especially in industries where hygiene is critical. Use approved

cleaning agents to prevent contamination.

- c. Lubricate moving parts as recommended by the manufacturer to prevent friction and ensure smooth operation.

- d. Ensure the belt tension is properly adjusted. Over-tightened belts can lead to excessive wear,

while loose belts may slip and affect performance.

- e. Monitor the conveyor for any unusual noises or vibrations, which could indicate mechanical

issues that need attention.

We also provide Modular Belt Conveyors in multiple cities like in Surat, Mumbai, Ghaziabad, and in many more...