Inclined belt conveyors are one of the most versatile and commonly used material handling systems in a variety of industries. They are particularly suited for moving goods and materials between different levels, such as from one floor to another or to load and unload trucks or containers. In Hyderabad, a growing industrial and logistics hub, the demand for inclined belt conveyors has risen due to the city's booming manufacturing, warehousing, and construction sectors. This article explores the key features, benefits, applications, and leading manufacturers of inclined belt conveyors in Hyderabad.

What is an Inclined Belt Conveyor?

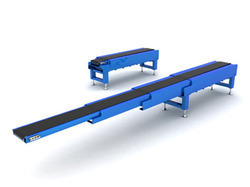

An inclined belt conveyor is a type of conveyor system that is set at an angle, allowing materials to be transported upwards or downwards between different heights. The belt, typically made from durable materials such as rubber or synthetic fabric, moves on a series of pulleys and rollers, which propel it forward. These conveyors are designed to handle both light and heavy loads, depending on the needs of the application.

Inclined belt conveyors are commonly used for bulk materials and packaged goods. They are often employed in industries such as manufacturing, food processing, warehousing, logistics, and construction to move goods efficiently over inclines, which manual labor or forklifts may find difficult to handle.

Key Features of Inclined Belt Conveyors

Inclined belt conveyors come with a range of features that make them ideal for a variety of industrial applications. These features include:

- Adjustable Incline: Many inclined belt conveyors allow for the angle of the incline to be adjusted, offering flexibility in handling different types of materials and applications. Some systems can be inclined at up to 30-45 degrees.

- Anti-Slip Belts: The belts used in inclined conveyors are often designed with a textured surface or cleats to prevent slippage, ensuring that the materials stay securely on the belt as they are transported upward or downward.

- Modular Design: Inclined belt conveyors can be customized with different belt lengths, widths, and configurations to suit specific needs. They are modular in nature, allowing for easy assembly, disassembly, and relocation.

- Durability: These conveyors are built to withstand the harsh environments of industrial settings, with components made from heavy-duty materials that are resistant to wear, corrosion, and impact.

- Low Maintenance: Inclined belt conveyors are designed for easy maintenance, with minimal moving parts and durable components that reduce the need for frequent repairs or replacements.

- Energy Efficiency: Many modern inclined belt conveyors are designed to be energy-efficient, reducing power consumption while maintaining high throughput rates.

Benefits of Using Inclined Belt Conveyors

There are several key benefits to using inclined belt conveyors in industrial operations:

- Efficient Material Handling: Inclined belt conveyors make it easy to move materials between different levels, whether loading or unloading trucks, transporting goods to upper floors, or moving materials from one section of a facility to another.

- Space-Saving Solution: These conveyors are ideal for facilities where space is limited, as they utilize vertical space efficiently, allowing for more productive use of the available floor area.

- Improved Safety: By automating the transportation of materials on inclines, these conveyors reduce the need for manual lifting and handling, minimizing the risk of injury and improving overall safety in the workplace.

- Cost-Effective: Inclined belt conveyors can significantly reduce labor costs and improve operational efficiency, leading to lower overall production costs and a faster return on investment.

- Versatility: Inclined belt conveyors are capable of handling a wide range of materials, including boxes, bags, bulk goods, and more. Their versatility makes them suitable for various industries such as logistics, warehousing, agriculture, and manufacturing.

- Customizable Design: The modular design of inclined belt conveyors allows them to be tailored to specific operational requirements, whether it’s adjusting the incline angle, belt width, or length.

Applications of Inclined Belt Conveyors in Hyderabad

In Hyderabad, inclined belt conveyors are used across a wide range of industries to enhance operational efficiency. Some of the primary applications include:

- Warehousing and Distribution: Inclined belt conveyors are widely used in warehouses and distribution centers to transport goods between different levels, load trucks, or move products from storage to packing stations.

- Manufacturing: In manufacturing facilities, these conveyors are used to move raw materials, components, and finished products between production lines, assembly areas, and storage spaces.

- Food and Beverage Industry: Inclined belt conveyors are ideal for transporting packaged food items, beverages, and other perishable goods. In Hyderabad's booming food processing sector, these conveyors help streamline production and distribution processes.

- Construction Industry: In construction and building materials industries, inclined conveyors are used to transport bulk materials such as sand, gravel, and cement between different elevations on construction sites.

- E-commerce and Retail: Inclined belt conveyors play a crucial role in the logistics and distribution operations of e-commerce companies, ensuring fast and efficient movement of packages from sorting areas to loading docks.

- Pharmaceuticals: Hyderabad, being a key player in the pharmaceutical industry, relies on inclined belt conveyors to handle the movement of medical supplies, drugs, and other sensitive products between different areas of production and packaging.

We also provide Inclined Belt Conveyors in multiple cities of India like in Delhi, Mumbai, Pune, and in many more...