Types of Conveyors Offered by Perfection Engineering Corporation

Belt Conveyors

Belt conveyors in Delhi are the most common and versatile types of conveyors used across industries. These conveyors use a continuous belt made from materials such as rubber, PVC, or polyurethane, which helps in moving goods from one point to another. Belt conveyors are ideal for transporting both lightweight and heavy items, making them suitable for industries like food processing, manufacturing, mining, and packaging.

Key Features:

Smooth and continuous operation

Suitable for long-distance transportation

Customizable length and width

Can handle various types of materials

Easy to install and maintain

Roller Conveyors

Roller conveyors are often used in industries where the transportation of goods is required without the need for a continuous belt. These conveyors are made up of multiple rollers placed at regular intervals. Roller conveyors come in two types: gravity-driven and motorized. The gravity-driven rollers rely on the natural movement of goods, while motorized rollers can move items with precision.

Key Features:

Low energy consumption in gravity rollers

Motorized rollers for precise movement

Can handle heavy loads

Ideal for assembly lines and warehouses

Customizable based on the requirements

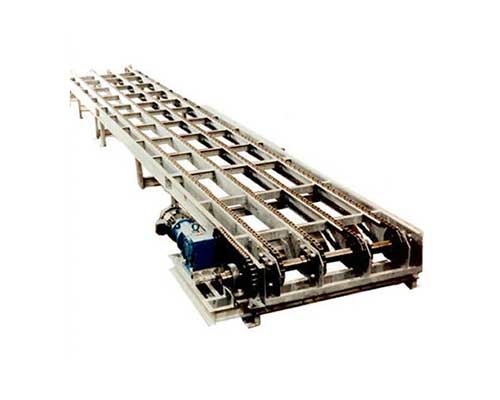

Chain Conveyors

Chain conveyors are designed for transporting heavy loads such as pallets, large containers, and industrial products. They use chains made of steel or plastic that run on rails, allowing the movement of goods with high weight and large dimensions. These conveyors are widely used in the automotive, heavy equipment, and manufacturing sectors.

Key Features:

Robust and durable construction

Suitable for heavy-duty applications

Low maintenance

Can be customized for complex layouts

Reliable in harsh industrial environments

Slat Conveyors

Slat conveyors consist of slats, or flat metal plates, attached to chains that move along a track. These conveyors are perfect for handling irregularly shaped, bulky items that cannot be easily handled on roller or belt conveyors. They are widely used in industries like automotive, electronics, and manufacturing.

Key Features:

Can handle a wide range of product shapes and sizes

Ideal for assembly lines

Easy to clean and maintain

Durable and long-lasting

Can be designed for curved paths

Screw Conveyors

Screw conveyors are specialized conveyors used primarily for transporting bulk materials, such as grains, coal, or chemicals. They use a helical screw that rotates within a trough to move the materials from one location to another. These conveyors are typically used in industries where vertical or inclined transport is necessary.

Key Features:

Ideal for bulk material handling

Can be used in horizontal, inclined, or vertical applications

Simple design with fewer moving parts

Low maintenance

Effective for both fine and coarse materials

Overhead Conveyors

Overhead conveyors are suspended from the ceiling and are commonly used in industries where floor space is limited. These conveyors move items along a fixed path using trolleys attached to a track system. They are ideal for painting, assembly, and garment industries.

Key Features:

Saves floor space

Flexible design for different industrial layouts

Can transport products around bends and over obstacles

Ideal for light to medium-weight items

Can be automated for increased efficiency

Pneumatic Conveyors

Pneumatic conveyors use air pressure to transport bulk materials such as powders, granules, and small particles through a pipeline. They are commonly used in industries like pharmaceuticals, food processing, and chemicals.

Key Features:

Clean and dust-free operation

Suitable for transporting fine materials

Can transport materials over long distances

Reduces material contamination

Easy to integrate into existing systems

Modular Conveyors

Modular conveyors are versatile and can be easily reconfigured based on the changing needs of the production line. They are made from interlocking plastic or metal modules, which makes them highly adaptable and easy to install.

Key Features:

Flexible and adaptable design

Can be easily expanded or reconfigured

Low maintenance

Suitable for various industries

Ideal for complex production lines

Benefits of Choosing Perfection Engineering Corporation’s Conveyor Systems

High-Quality Materials

Perfection Engineering Corporation uses only the finest materials in the construction of its conveyor systems. Whether it’s stainless steel, aluminum, or high-quality polymers, each material is carefully chosen for its durability, strength, and suitability for the intended application.

Customization Options

Each industry has its unique needs, and Perfection Engineering Corporation understands this. The company offers fully customizable conveyor systems that can be tailored in terms of size, design, material, and functionality to meet specific client requirements.

Energy Efficiency

The conveyor systems from Perfection Engineering Corporation are designed with energy efficiency in mind. Whether it’s the use of gravity in roller conveyors or the integration of energy-efficient motors, the company ensures that its systems help clients reduce energy consumption.

Cost-Effective Solutions

The company focuses on providing high-quality products at competitive prices. Whether you’re a small business or a large-scale industrial unit, Perfection Engineering Corporation has a range of conveyor solutions that fit various budget constraints.

Durability and Longevity

Conveyor systems often face harsh working conditions, and Perfection Engineering Corporation ensures that its products are built to last. The use of durable materials and precision engineering techniques ensures that the conveyor systems have a long service life, even in demanding industrial environments.

Ease of Installation and Maintenance

Perfection Engineering Corporation’s conveyor systems are designed for easy installation and maintenance. The company provides comprehensive support during the installation process and offers maintenance services to ensure the smooth operation of the conveyors over time.

Advanced Technology

The company integrates the latest technological advancements into its conveyor systems, such as automation, real-time monitoring, and smart controls. This not only increases productivity but also ensures precise handling of goods.

Reasons to Choose Perfection Engineering Corporation

Expertise and Experience: With years of experience in the industry, Perfection Engineering Corporation has built a reputation for delivering top-notch conveyor solutions.

Customer-Centric Approach: The company works closely with its clients to understand their specific needs and provides personalized conveyor systems.

Innovation: The company is constantly innovating, adopting new technologies, and enhancing its product line to stay ahead of industry trends.

After-Sales Support: Perfection Engineering Corporation offers excellent after-sales service, including maintenance, repairs, and upgrades, ensuring that clients get the most out of their conveyor systems.