Overview of Screw Auger Conveyor Systems

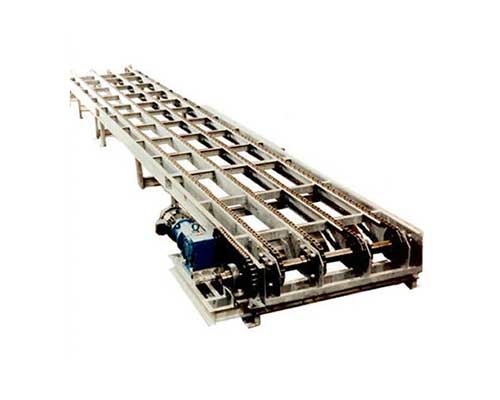

A Screw Auger Conveyor System is designed to move bulk materials efficiently. The system consists of a helical screw (auger) that rotates inside a tube or trough. As the screw rotates, materials are pushed forward along the axis of the screw, allowing for the continuous and controlled transportation of bulk goods. The movement of the materials occurs through a combination of rotation and friction, making screw conveyors a simple yet highly effective method for moving solid or semi-solid materials.

At Perfection Engineering Corporation, the Screw Auger Conveyor Systems are engineered to provide superior performance, durability, and reliability. The systems are available in various configurations, including horizontal, inclined, or vertical, depending on the application. With a strong focus on customization, the company ensures that every screw auger conveyor system is designed to meet the specific requirements of the client’s industry and application.

Applications of Screw Auger Conveyor Systems

Agriculture:

In the agricultural sector, screw conveyors are commonly used to transport grains, seeds, fertilizers, and animal feed. These conveyors help streamline the handling and processing of bulk agricultural materials, improving efficiency in farming operations.

Food Processing:

The food industry utilizes screw conveyors for the movement of food ingredients such as flour, sugar, grains, and powders. They are also used in handling semi-solid food products like dough and pastes. The system’s ability to maintain hygiene and prevent contamination makes it ideal for food processing.

Mining and Construction:

In mining and construction, screw auger conveyors are used for transporting abrasive materials like cement, sand, gravel, and ores. The robust design of these conveyors allows them to withstand harsh conditions and heavy loads, making them indispensable for these industries.

Chemical and Pharmaceutical Industries:

In chemical and pharmaceutical production, screw conveyors are used to handle powders, granules, and other fine materials. These systems are designed with special coatings and materials to prevent corrosion and ensure the safe handling of chemical substances.

Key Features of Screw Auger Conveyor Systems by Perfection Engineering Corporation

Durability and Strength:

At Perfection Engineering Corporation, the screw auger conveyor systems are built to last. The materials used in construction are of the highest quality, ensuring resistance to wear, corrosion, and harsh environmental conditions. This durability makes the conveyors suitable for demanding applications, including heavy-duty industrial use.

Customization Options:

Understanding that different industries have unique material handling requirements, Perfection Engineering Corporation offers fully customizable screw conveyor systems. Clients can choose from various configurations, including length, diameter, material of construction, and design features. This flexibility ensures that each system is tailored to the specific operational needs of the customer.

Ease of Maintenance:

Screw auger conveyor systems are designed for minimal maintenance. The simple design with fewer moving parts reduces the chances of mechanical failure. Regular maintenance tasks like lubrication, inspection, and cleaning are easy to perform, contributing to longer operational life and lower downtime.

Energy Efficiency:

Perfection Engineering Corporation focuses on designing energy-efficient screw conveyors. The optimized design reduces energy consumption while maintaining high operational efficiency, helping businesses lower their operating costs.

Safety Features:

Safety is a priority in industrial equipment, and the screw auger conveyor systems from Perfection Engineering Corporation are no exception. The systems are equipped with safety features such as enclosed troughs to prevent spillage, overload protection to avoid motor damage, and automatic shut-off mechanisms to enhance worker safety.

Hygienic Design for Food and Pharmaceutical Industries:

For industries like food processing and pharmaceuticals, maintaining hygiene is crucial. Perfection Engineering Corporation ensures that its screw conveyors meet the strictest hygiene standards. The use of food-grade materials, seamless designs, and easy-to-clean components ensures that the conveyors prevent contamination and uphold sanitation standards.

Benefits of Screw Auger Conveyor Systems

Efficient Material Handling:

Screw conveyors offer a highly efficient way to transport materials over both short and long distances. Their ability to handle a wide variety of bulk materials, from powders to granules and liquids, makes them versatile and efficient in various industrial settings.

Cost-Effective Solution:

With low operational and maintenance costs, screw conveyors provide a cost-effective material handling solution. The simple design and minimal energy consumption contribute to long-term savings for businesses.

Flexibility and Versatility:

Screw auger conveyors can be used for both horizontal and inclined transport, making them versatile for different installation setups. Additionally, they can handle materials in various states, including solid, semi-solid, and liquid.

Space-Saving Design:

Screw conveyors require less space compared to other conveyor types, making them suitable for industries where space is limited. Their compact design allows for easy installation in areas with spatial constraints.

Minimal Dust and Material Spillage:

The enclosed design of screw conveyors minimizes the risk of dust and material spillage during transport. This feature is particularly important in industries handling fine powders or hazardous materials.

Why Choose Perfection Engineering Corporation?

Proven Expertise:

Perfection Engineering Corporation has years of experience in the design and manufacturing of screw auger conveyor systems. The company’s deep knowledge and expertise in material handling ensure that clients receive high-performance systems tailored to their needs.

Commitment to Quality:

Every screw conveyor produced by Perfection Engineering Corporation is crafted using the finest materials and undergoes rigorous quality checks. The company adheres to strict quality control measures, ensuring the reliability and durability of its products.

Customer-Centric Approach:

At Perfection Engineering Corporation, customer satisfaction is a top priority. The company works closely with clients to understand their material handling requirements and provides customized solutions that meet specific industrial needs.

After-Sales Support:

The company offers comprehensive after-sales support, including maintenance services, spare parts, and technical assistance. This commitment to customer service ensures that clients can rely on their screw conveyors for years to come.