Rubber conveyor belts are the backbone of material transport in various industries, ensuring a smooth and consistent flow of raw materials, products, and waste. Whether for heavy-duty applications like mining and construction or lightweight processes such as food and packaging, rubber conveyor belts are a crucial component of industrial operations. Perfection Engineering Corporation’s belts stand out for their superior design, strength, and longevity, making them a preferred choice for clients in Delhi and beyond.

Overview of Rubber Conveyor Belts:

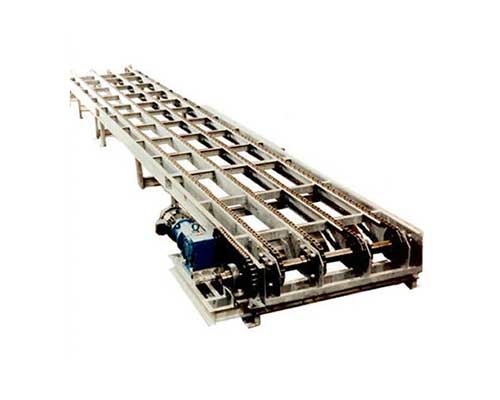

A rubber conveyor belt is an essential tool used to transport various materials over distances, whether horizontally or at an incline. These belts are crafted from a mix of natural and synthetic rubber compounds, which provide excellent durability, flexibility, and resistance to environmental and operational stress.

Rubber conveyor belts consist of three main components:

Top Cover Layer: Made from high-quality rubber, this layer protects the belt from wear and tear caused by materials such as coal, ore, or gravel. It provides the first line of defense against abrasion, chemicals, and extreme temperatures.

Carcass (Reinforcement Layer): This is the heart of the conveyor belt, providing tensile strength and resistance to stretching. The carcass is typically made from materials like polyester, nylon, or steel cords, depending on the application and load-bearing requirements.

Bottom Cover Layer: This layer, also made from rubber, helps to reduce friction between the belt and the machinery, ensuring smoother operation and longer service life.

Perfection Engineering Corporation specializes in a variety of rubber conveyor belts, including general-purpose belts, heat-resistant belts, oil-resistant belts, and fire-retardant belts, each designed to meet the specific needs of different industries.

Features of Rubber Conveyor Belts Manufactured by Perfection Engineering Corporation:

Durability and Strength: Perfection Engineering Corporation’s rubber conveyor belts are known for their high durability and strength, capable of withstanding heavy loads and extreme operational conditions. The high-quality rubber and superior construction materials used ensure that the belts are resistant to wear and tear, even in abrasive environments like mining and construction.

Heat and Chemical Resistance: For industries like steel, cement, and chemical manufacturing, the ability of a conveyor belt to resist high temperatures and corrosive chemicals is critical. Perfection Engineering Corporation offers heat-resistant rubber conveyor belts that can withstand temperatures as high as 200°C. Additionally, their chemical-resistant belts provide protection against oils, fats, and other chemical substances, ensuring longevity and reliability in harsh industrial environments.

Flexibility and Versatility: The rubber conveyor belts produced by Perfection Engineering Corporation are incredibly versatile, allowing for customization according to the customer’s specifications. Whether the belts need to be flat, cleated, or inclined, the company’s design and manufacturing teams ensure that the belts meet the exact requirements of the application. This flexibility makes their conveyor belts suitable for a wide range of industries, from heavy-duty mining to light packaging.

Cost-Effective Solutions: In addition to their high quality, the conveyor belts from Perfection Engineering Corporation are cost-effective. Their long service life, low maintenance requirements, and ability to handle high operational loads translate into reduced downtime and operational costs for businesses. This combination of durability and affordability makes them a smart investment for industries looking to improve efficiency without breaking the bank.

Eco-Friendly Manufacturing: Perfection Engineering Corporation takes pride in its eco-friendly manufacturing processes. The rubber used in their conveyor belts is sourced responsibly, and the company ensures minimal wastage during the production process. The belts are designed for reusability and recyclability, aligning with modern industry standards for sustainability.

Applications of Rubber Conveyor Belts:

Mining and Quarrying: The mining industry requires conveyor belts that can handle large amounts of rock, ore, and other raw materials over long distances. The belts need to be durable, resistant to abrasion, and capable of carrying heavy loads. Perfection Engineering Corporation’s belts are specially designed to meet these demanding requirements, offering high tensile strength and resistance to wear.

Cement and Construction: Conveyor belts in the construction and cement industry are used to transport raw materials such as sand, limestone, and cement. These materials can be harsh on equipment, which is why Perfection Engineering Corporation’s belts are designed to withstand the abrasive nature of these products while ensuring continuous operation.

Food Processing and Packaging: In the food processing industry, conveyor belts must meet stringent hygiene standards. Perfection Engineering Corporation offers belts made from food-grade rubber that are safe for transporting food products. These belts are also resistant to oils and fats, making them ideal for food processing applications.

Power Plants: Conveyor belts in power plants are used to transport coal, ash, and other materials that are essential for the operation of the plant. The heat-resistant and flame-retardant properties of Perfection Engineering Corporation’s conveyor belts make them an ideal choice for power plants, where safety and reliability are paramount.

Logistics and Warehousing: In the logistics and warehousing industry, conveyor belts are used for sorting and transporting packages. Perfection Engineering Corporation provides belts that are durable, flexible, and efficient, ensuring smooth operation in fast-paced environments.

Why Choose Perfection Engineering Corporation?

Expertise and Experience: With years of experience in the conveyor belt manufacturing industry, Perfection Engineering Corporation has the expertise to provide tailored solutions for any material handling requirement. Their team of engineers and technicians are well-versed in the latest technologies and industry standards, ensuring that customers receive top-notch products.

Customization: Every industry has different requirements when it comes to conveyor belts, and Perfection Engineering Corporation excels at providing customized solutions. Whether a client needs a belt that can withstand extreme temperatures or one that is resistant to chemicals, the company’s engineers work closely with customers to deliver a product that meets their exact specifications.

Quality Assurance: Quality is at the core of everything Perfection Engineering Corporation does. Every belt undergoes rigorous testing to ensure it meets the highest standards of durability, performance, and safety. The company’s commitment to quality has earned it the trust of industries across Delhi and beyond.