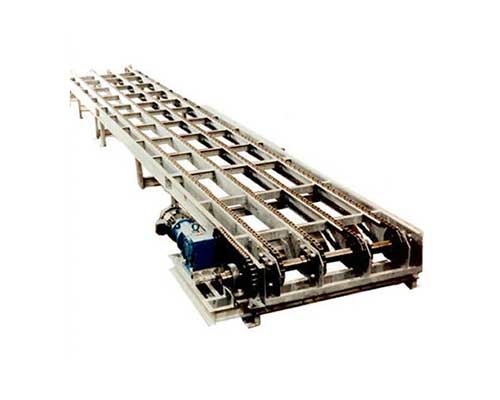

What is a Drag Chain Conveyor?

A Drag Chain Conveyor is a type of conveyor system that utilizes a chain to drag materials along a track. Unlike traditional belt conveyors, which rely on a continuous belt, Drag Chain Conveyors employ a series of metal chains or links to transport heavy and bulk materials. This design enables them to handle a variety of materials, including powders, granules, and larger bulk items.

Key Components of Drag Chain Conveyors

Chains: The heart of the system, typically made from high-strength steel, ensures durability and resistance to wear and tear.

Sprockets: These are the wheels that the chains loop around, facilitating the movement of the chains and the materials they carry.

Trays or Troughs: The material-carrying surface, often designed with high sidewalls to prevent spillage.

Drive Mechanism: Typically consists of a motor and gearbox that provides the necessary power to move the chain.

Guides and Supports: These ensure the proper alignment of the chain and support the entire conveyor structure.

Advantages of Drag Chain Conveyors

High Load Capacity

Drag Chain Conveyors are designed to carry heavy loads, making them ideal for industries dealing with substantial material volumes. Their robust construction allows them to transport large, bulky items without compromising efficiency.

Durability and Reliability

Built from high-quality materials, Drag Chain Conveyors are engineered to withstand harsh operating conditions, including extreme temperatures, moisture, and abrasive materials. This durability translates into a longer lifespan, reducing the need for frequent replacements.

Versatility

These conveyors can be adapted for various applications, making them suitable for a wide range of materials, including aggregates, grains, and even recyclables. This versatility allows businesses to streamline their operations by using a single system for multiple material types.

Minimal Maintenance

Unlike traditional conveyor systems that require regular belt adjustments and replacements, Drag Chain Conveyors have fewer moving parts, resulting in lower maintenance requirements. This feature allows operators to focus on production rather than maintenance.

Space Efficiency

The design of Drag Chain Conveyors can be customized to fit specific space constraints, allowing for overhead installations or configurations that optimize floor space. This flexibility is particularly beneficial in crowded industrial environments.

Applications of Drag Chain Conveyors

Drag Chain Conveyors find applications across a multitude of industries:

Manufacturing: Used for transporting raw materials and finished products within factories.

Mining: Ideal for moving minerals, coal, and other heavy materials from extraction sites to processing areas.

Food Processing: Employed in transporting grains, seeds, and other bulk food items.

Recycling: Suitable for handling various recyclable materials in waste management facilities.

Agriculture: Used for transporting grains, seeds, and other agricultural products from one location to another.

Choosing the Right Drag Chain Conveyor

When selecting a Drag Chain Conveyor for your operations, consider the following factors:

Material Type: Identify the materials you need to transport to ensure compatibility with the conveyor’s design and capacity.

Load Capacity: Assess the maximum load the conveyor must handle to choose a model that meets your needs.

Operational Environment: Consider factors like temperature, moisture, and the presence of abrasive materials when selecting materials for the conveyor.

Space Constraints: Evaluate your facility layout to determine the best configuration for the conveyor system.

Customization Needs: Look for manufacturers who offer customization options to meet specific requirements for your operation.

Why Choose Perfection Engineering Corporation?

Perfection Engineering Corporation stands out in the market for several reasons:

Quality Assurance: We use high-grade materials and adhere to strict quality control measures during manufacturing to ensure our conveyors meet international standards.

Expertise: With years of experience in the industry, our team possesses in-depth knowledge of material handling systems and can provide expert advice tailored to your unique requirements.

Customer-Centric Approach: We prioritize customer satisfaction and work closely with our clients to deliver solutions that enhance productivity and efficiency.

After-Sales Support: Our commitment to our clients continues long after the sale, offering maintenance, repair services, and support to ensure optimal performance.