Perfection Engineering Corporation is present here to fulfill your requirements, without forcing you to compromise. We have the most experienced professionals for manufacturing and supplying the best Industrial Conveyors according to the needs of our valued customers. The use of industrial conveyor in Bangalore that we manufacture vary with the kind of product that you will move with the help of conveyor.

An industrial conveyor in Bangalore system is a mechanical handling equipment that is useful in applications that involve transportation of bulky or heavy things. We, at Perfection Engineering Corporation, have our core focus on providing high quality and excellent customer services. We provide different types of conveyors depending on the various needs and desires of the industry. The best industrial conveyors provided by us helps you to quickly and efficiently move a wide variety of materials which in turn makes these conveyors very famous in the packaging and material handling industries.

Bangalore, known for its thriving industrial base and rapid economic growth, is home to a diverse range of industries, from manufacturing and logistics to technology and automation. One key aspect of industrial efficiency in this dynamic city is the use of industrial conveyors. Industrial conveyors are mechanical handling systems used to transport materials efficiently across various stages of production, packaging, warehousing, and shipping. This article will delve into the types, applications, and benefits of industrial conveyors in Bangalore.

Types of Industrial Conveyors

Industrial conveyors come in various forms, each designed for specific applications. Some of the most common types used in Bangalore's industrial sectors include:

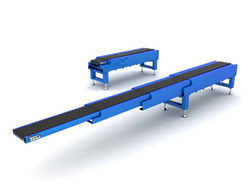

- a. Belt Conveyors: Belt conveyors use a continuous loop of material, typically made of rubber or fabric, to move items across distances. They are widely used in industries like manufacturing, packaging, and food processing for their versatility in handling products of different sizes and shapes.

- b. Roller Conveyors: Roller conveyors feature a series of rollers that allow items to be moved by gravity or manual pushing. These conveyors are ideal for transporting heavy materials, boxes, or pallets in industries like warehousing, logistics, and automotive assembly.

- c. Chain Conveyors: Chain conveyors use chains to move items along a track and are suitable for transporting heavy loads, including automotive parts, metal containers, and bulk materials. They are commonly used in industries like automotive manufacturing and heavy engineering.

- d. Modular Belt Conveyors: Modular belt conveyors use interlocking plastic pieces to create a conveyor belt. This system is highly flexible and allows easy replacement of individual sections. Modular belts are used in industries like food processing, packaging, and pharmaceuticals.

- e. Inclined Conveyors: Inclined conveyors are designed to move materials between different elevations, making them essential in industries like food processing, logistics, and warehousing for space optimization.

- f. Screw Conveyors: Screw conveyors use a helical screw element to move materials, primarily in bulk solids such as grains, powders, or chemicals. They are used extensively in industries like agriculture, chemical processing, and mining.

- g. Pneumatic Conveyors: Pneumatic systems use air pressure to move bulk materials through pipelines. These systems are often used in industries like food and beverage, pharmaceuticals, and chemicals, where contamination-free transport is critical.

Applications of Industrial Conveyors in Bangalore

With Bangalore's diverse industrial landscape, industrial conveyors find applications across numerous sectors:

- a. Manufacturing: In manufacturing plants, conveyors are used to transport raw materials, semi-finished products, and finished goods across different production stages, improving overall efficiency and reducing manual labor.

- b. Logistics and Warehousing: Warehouses and logistics centers in Bangalore rely heavily on conveyors for moving goods between storage areas, loading docks, and shipping stations, ensuring fast and accurate order fulfillment.

- c. Automotive Industry: The automotive industry in Bangalore uses heavy-duty conveyors like chain conveyors and roller conveyors to transport large and heavy parts, such as engines and chassis, through various stages of assembly.

- d. Food and Beverage: The food processing sector uses conveyors such as belt and modular systems to transport food products in hygienic conditions, reducing contamination risks while increasing production speed.

- e. Pharmaceutical Industry: In pharmaceutical manufacturing, conveyors are used to transport raw materials, pills, and packaged medicines through various production stages, maintaining high hygiene and safety standards.

- f. Packaging Industry: Packaging units in Bangalore rely on conveyors to move products between assembly lines and packaging machines, automating the packing process and reducing human intervention.

Benefits of Industrial Conveyors

Industrial conveyors offer numerous advantages to businesses in Bangalore, including:

- Improved Efficiency: Conveyors automate the transportation of goods, eliminating the need for manual handling and significantly speeding up production processes.

- Reduced Labor Costs: By automating material handling, conveyors reduce the need for manual labor, lowering labor costs and minimizing the risk of human errors.

- Increased Safety: Industrial conveyors reduce the need for employees to manually lift and move heavy materials, reducing the risk of workplace injuries and improving overall safety.

- Space Optimization: Conveyor systems, especially inclined and vertical conveyors, help optimize space in facilities, enabling efficient material flow even in limited spaces.

- Customizable Designs: Conveyor systems can be customized to meet the specific needs of different industries, including size, shape, and material-handling capacity, making them highly adaptable to various operational requirements.

- Durability: Industrial conveyors are built with robust materials, ensuring long-term durability even in demanding environments, reducing maintenance costs and downtime.

- Enhanced Product Flow: Conveyors ensure a smooth, continuous flow of materials, reducing bottlenecks in production and improving overall throughput.

Considerations When Choosing an Industrial Conveyor System

>

Selecting the right industrial conveyor system for your business in Bangalore requires careful consideration of several factors:

- a. Type of Materials: The nature of the materials being transported (weight, size, bulk) will determine the best conveyor type, such as belt or roller conveyors.

- b. Load Capacity: Ensure the conveyor system can handle the maximum load you expect to transport to avoid overloading and system breakdown.

- c. Space Availability: Evaluate the available space in your facility to determine the size and layout of the conveyor system, ensuring it integrates seamlessly without disrupting operations.

- d. Maintenance Requirements: Choose conveyor systems that require minimal maintenance to reduce downtime and long-term operational costs.

- e. Energy Efficiency: Consider conveyors with energy-efficient designs to minimize operational costs and environmental impact.

We also provide Industrial Conveyor System in multiple cities like in Delhi, Noida, Ghaziabad, and in many more...